Nylon is a ubiquitous fabric woven into every aspect of modern life—from clothing and carpets to industrial and medical materials—thanks to its durability and affordability. But have we truly considered the hidden environmental toll behind its convenience? Its origins trace back to fossil fuels extracted through disruptive drilling, releasing pollutants and greenhouse gases that fuel climate change. The chemical process of transforming these resources into nylon fibers consumes vast energy, tying its existence to ongoing fossil fuel reliance. Once discarded, nylon’s resilience causes it to persist in landfills and oceans for decades, shedding microfibers that threaten marine ecosystems and enter our food supply. As we continue to produce and consume this synthetic fiber, the cycle of environmental harm—climate impacts, water pollution, and microplastic contamination—intensifies. Could embracing sustainable alternatives and smarter waste management help mitigate this hidden crisis before it’s too late?

Unveiling the Hidden Environmental Costs of Nylon

Nylon is one of those materials we encounter every day—whether in our clothes, carpets, or even the fishing lines and seat belts that keep us safe. Its versatility, durability, and affordability have made it a cornerstone of modern manufacturing, supporting countless industries and routines. But behind its widespread use lies a hidden story of environmental costs that often go unnoticed. As we rely more on synthetic fibers like nylon, it’s worth pausing to consider the broader impact of these materials on our planet.

The process of making nylon begins deep underground, where oil and natural gas are extracted through drilling. This extraction can cause significant environmental disruption, including habitat destruction, water contamination, and greenhouse gas emissions. Once obtained, these fossil fuels are refined into chemical building blocks like hexamethylenediamine and adipic acid—key ingredients in nylon production. The refining process is energy-intensive and releases pollutants such as volatile organic compounds, sulfur dioxide, and nitrogen oxides, contributing to air pollution and climate change.

Transforming these chemicals into nylon involves a process called polymerization. Small molecules, known as monomers, are linked together to form long, repeating chains—this is the foundation of nylon’s molecular structure. This step relies heavily on heat and catalysts derived from fossil fuels, which provide the energy necessary for the chemical reactions. As the monomers bond, water molecules are released as byproducts. The resulting long chains are then spun into fibers, which are woven into fabrics used in countless products. Each stage depends on a continuous input of fossil fuels, reinforcing the link between nylon’s creation and ongoing resource extraction.

The dependence on non-renewable resources extends beyond raw materials; it also involves the energy used throughout production. The entire process consumes large amounts of electricity and heat, predominantly sourced from coal, oil, or natural gas power plants. As a result, every yard of nylon fabric carries an embedded carbon footprint, making its manufacturing a significant contributor to greenhouse gas emissions. Over time, this cycle has played a notable role in accelerating climate change, highlighting how synthetic fiber production is intertwined with fossil fuel consumption.

Once in use or discarded, nylon’s environmental impact continues. Its durability means it doesn’t break down easily, lingering in landfills for decades or even centuries. Washing nylon garments releases microfibers—tiny plastic particles smaller than a grain of sand—that wash into water systems. These microplastics are now recognized as a major form of water pollution, infiltrating oceans, lakes, and rivers, where they threaten marine ecosystems and enter the food chain. Despite efforts to develop filters and better washing techniques, microfiber pollution remains a persistent challenge, linking our everyday routines to long-term environmental harm.

This resilience of nylon waste presents a profound challenge. Unlike organic waste that decomposes naturally, nylon and other plastics fragment into microplastics that contaminate soils and waterways. Marine animals ingest these particles, which can cause injury or death, and these microplastics often find their way back onto our plates through seafood. Recycling efforts are expanding but still fall far short of addressing the scale of nylon waste generated globally. As consumption continues to rise, so does the accumulation of persistent microplastics, amplifying the environmental costs associated with this ubiquitous material.

Tracing Nylon’s Origins from Deep Earth to Synthetic Fiber

Nylon’s journey begins deep underground, where oil and natural gas are extracted through drilling. This initial step is far from harmless; it often leads to habitat destruction, water contamination, and significant greenhouse gas emissions. These fossil fuels serve as the raw materials for nylon’s chemical building blocks, such as hexamethylenediamine and adipic acid, which are essential for its creation. The refining process to produce these chemicals is highly energy-intensive, releasing pollutants like volatile organic compounds (VOCs), sulfur dioxide, and nitrogen oxides into the atmosphere. These emissions contribute to both local air pollution and broader climate change, illustrating how nylon’s origins are rooted in environmental disruption.

Once obtained, these hydrocarbons undergo chemical transformation into nylon. This process, known as polymerization, involves linking small molecules called monomers into long, repeating chains—forming the basis of nylon’s molecular structure. Polymerization relies heavily on heat and catalysts derived from fossil fuels, which provide the energy needed for these reactions. During this process, water molecules are released as byproducts, and the resulting polymer chains are spun into fibers. Each stage depends on continued fossil fuel input, reinforcing the connection between nylon production and ongoing resource extraction.

The energy used throughout nylon manufacturing is predominantly sourced from coal, oil, or natural gas power plants. This dependence means that every yard of nylon fabric carries an embedded carbon footprint, making its production a notable contributor to greenhouse gas emissions. From raw material refining to fiber spinning, the entire process is fueled by non-renewable resources. Over time, this cycle has significantly contributed to climate change, highlighting the environmental cost embedded in the very fabric of our everyday products.

Beyond its creation, nylon’s durability becomes a double-edged sword after use. Its resistance to degradation means it persists in landfills for decades or even centuries. When we wash nylon garments, microfibers—tiny plastic particles smaller than a grain of sand—shed from the fabric and wash into water systems. These microplastics are now recognized as a major water pollutant, infiltrating oceans, lakes, and rivers. Marine life ingests these particles, which can cause injury or death, and microplastics often find their way into the human food chain through seafood consumption.

The resilience of nylon waste extends into soils and aquatic environments, where it fragments into microplastics that can travel vast distances. These tiny particles contaminate ecosystems, threaten wildlife, and disrupt natural processes. Despite growing recycling efforts, the scale of nylon waste remains overwhelming, and current measures fall far short of addressing the problem. As the production and disposal of nylon continue to rise, so does the accumulation of microplastics, creating a persistent environmental challenge that is hard to ignore.

Understanding nylon’s origins and lifecycle reveals a complex web of environmental costs hidden behind a seemingly simple, durable fabric. Its reliance on fossil fuels and the associated pollution are deeply intertwined with broader issues like climate change and ecosystem degradation. Recognizing these foundational processes is crucial for anyone interested in the true impact of synthetic fibers. It underscores the importance of seeking sustainable alternatives and rethinking how we produce, consume, and dispose of materials like nylon. Only by confronting its roots can we begin to reduce its footprint and move toward a more responsible, eco-friendly future.

Nylon in Modern Life: A Durable Material with a Troubling Footprint

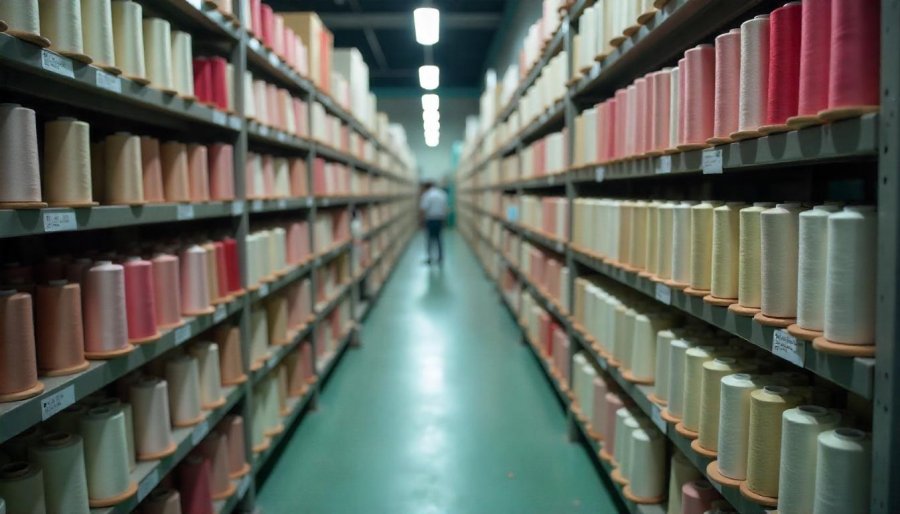

Nylon’s presence in our daily lives is more extensive than many of us realize. From the clothes we wear and the carpets under our feet to the sports gear, medical supplies, and even the packaging that surrounds us, this synthetic fiber has become a cornerstone of modern manufacturing. Its durability, affordability, and versatility make it an attractive choice across industries, enabling products that last longer and perform better. But behind this convenience lies a complex environmental story that often remains invisible to the consumer.

The journey from raw material to finished product begins deep underground, where oil and natural gas are extracted through drilling. These fossil fuels are the foundation of nylon’s chemical components, such as hexamethylenediamine and adipic acid. The extraction process itself can cause habitat destruction, water pollution, and release significant greenhouse gases. Once obtained, these hydrocarbons undergo energy-intensive refining to produce the chemicals needed for nylon, releasing pollutants like volatile organic compounds and sulfur dioxide into the atmosphere. This initial phase ties nylon’s existence to ongoing environmental disruption, setting the stage for its broader impact.

Transforming these chemicals into nylon involves a process called polymerization, where small molecules called monomers are linked into long, repeating chains. This step relies heavily on heat, catalysts, and substantial energy inputs from fossil fuel power plants. The resulting long chains are spun into fibers used in countless applications—clothing, upholstery, industrial materials—each step drawing on a continuous supply of non-renewable resources. As a result, the production of nylon is a notable contributor to global carbon emissions, embedding its footprint into everything we make and use.

Once in use, nylon’s durability becomes both an advantage and a challenge. Its resistance to decay means it can last for decades or even centuries in landfills, slowly breaking down into microplastics—tiny particles smaller than a grain of sand. When we wash nylon garments, these microfibers shed and wash away, contaminating water systems worldwide. Oceans, lakes, and rivers become repositories for these plastics, which threaten marine life and enter the food chain. Despite advances in filtration and washing techniques, microfiber pollution remains stubbornly persistent, linking routine household activities to long-term environmental harm that’s difficult to see but impossible to ignore.

The environmental footprint of nylon extends beyond water pollution. Its resilience means that discarded nylon items persist in landfills, gradually fragmenting into microplastics that contaminate soils and waterways over time. Marine animals ingest these particles, leading to injuries or death, and microplastics often find their way onto our dinner plates through contaminated seafood. Recycling efforts are expanding, but they still fall far short of addressing the sheer volume of nylon waste generated globally. As production and consumption continue to grow, so does the accumulation of these tiny pollutants, creating a persistent and widespread environmental challenge. Recognizing the scale of this impact underscores the urgent need for systemic change—shifting toward sustainable alternatives and smarter waste management practices—to reduce nylon’s footprint and protect the ecosystems upon which we all depend.